Sustainable fertilizer production increasingly depends on efficient pomace drying machine and disciplined moisture reduction design, because many organic by-products enter the processing line with moisture levels above 90%. A responsible water reduction process lowers transport weight, reduces odor risk, stabilizes storage, and improves downstream granulation quality for organic fertilizer granules or pellet making. In addition, a well-structured procedure can combine dewatering, composting, and thermal drying into a coordinated system that reduces energy loss and avoids unnecessary rework. Therefore, sustainable practices in the pomace drying stage focus on raw material selection, staged dehydration, heat recovery, and dust and odor control, while also protecting final fertilizer particle strength and uniformity.

Which high‑moisture organic waste raw materials suit pomace drying for organic fertilizer production, and what benefits do different industries gain?

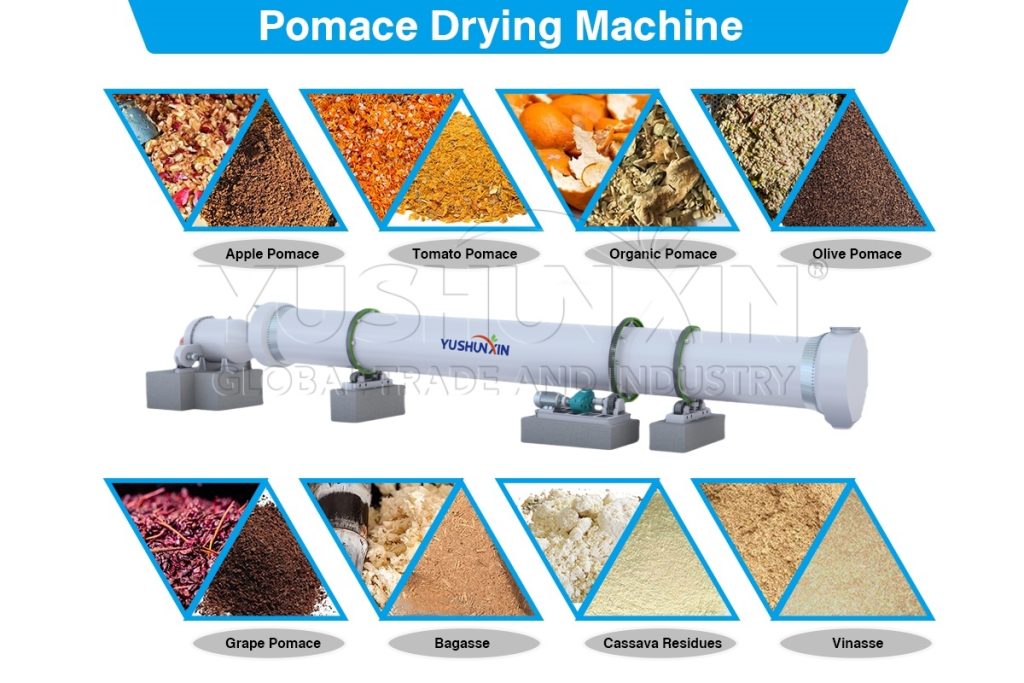

Several industries generate high moisture organic waste that fits pomace fertilizer production after proper dewatering and stabilization. The fruit and beverage sector often provides apple pomace, grape pomace, citrus pomace, pineapple pomace, and berry press cake; these materials typically offer fermentable organics that support composting and later granulating into stable fertilizer granules. The sugar and starch sector can contribute beet pulp, cassava residue, and sweet potato pulp, which usually requires careful dehydration because sticky solids can affect the granulator feed consistency. The brewery and distillery sector supplies spent grain and vinasse solids; these streams frequently deliver nitrogen value but can create odor, so a controlled drying process supports compliance and improves storage safety. The vegetable and oil-processing sector contributes tomato pomace, olive pomace, and seed cake blends; these blends can improve organic matter content but often require moisture control to prevent caking during pelletizing. Each industry benefits from the same sustainable target: a repeatable production process that converts wet by-products into standardized organic fertilizer pellets with lower logistics cost and higher market acceptance.

How can a four‑stage moisture reduction process reduce pomace from above 90% moisture to below 10% while improving granulation performance?

A sustainable procedure often applies four coordinated stages that move from mechanical separation to thermal finishing, because a single machine rarely achieves stable quality at low operating cost. The first stage typically uses a dewatering machine or press to remove free water quickly, which reduces load on later drying equipment and lowers energy consumption per ton of pomace. The second stage often uses composting in a controlled compost system or compost machine; this step supports hygienic stabilization, odor mitigation, and improved texture for subsequent granulation. The third stage frequently relies on a rotary drum dryer as the main drying machinery, because a drum design can maintain continuous throughput and deliver consistent water reduction across varying particle sizes and fiber content. The fourth stage often introduces a wet granulation step with a granulator or pelletizer to form durable fertilizer granules, because controlled binder addition and moisture tuning can raise pellet strength and reduce fines. This staged technology design helps a manufacturer reach moisture targets below 10% while also improving pellet making stability, particle uniformity, and packaging readiness.

What rotary drum dryer features support sustainable pomace drying, lower energy use, and stable fertilizer particle quality?

A sustainable pomace drying process depends on stable heat and mass transfer, and a rotary drum dryer supports that objective through continuous mixing, controlled residence time, and adaptable temperature zones. A drum dryer system can include optimized lifting flights that increase contact between hot gas and moist solids, which improves dehydration efficiency and reduces over-drying that harms organic matter quality. A practical design also uses variable speed control to adjust retention time for different pomace blends, because grape pomace and citrus pomace often behave differently in a drying chamber. In addition, a rotary drum dryer can integrate insulation, sealed feeding and discharge structures, and airflow management to limit heat loss and fugitive emissions during fertilizer manufacturing. Many production lines also benefit from heat recovery options such as exhaust-to-air preheating, because recovered heat reduces fuel use while keeping the drying procedure stable. Therefore, drum dryer equipment selection influences energy intensity, final moisture uniformity, and downstream granulating behavior for consistent fertilizer granule size distribution.

Which sustainability controls reduce odor, dust, and wastewater during pomace fertilizer production while protecting granulation consistency?

Environmental control practices can strengthen sustainability when pomace moves through dewatering, composting, drying, and granulation stages. A closed transfer design that uses sealed conveyors and controlled hopper vents can reduce odor release, which supports community standards and plant hygiene. A dust collection system such as cyclone plus bag filter can reduce particulate loss during drying and during pelletizing, which also protects final fertilizer pellet appearance and reduces housekeeping labor. Wastewater control also matters, because the dewatering stage can generate filtrate that contains soluble organics; a plant can route that stream to anaerobic treatment, aerobic treatment, or recirculation to compost moisture control, depending on site constraints. Process instrumentation can further support sustainability, because online moisture monitoring and temperature feedback loops reduce off-spec batches and repeated drying cycles. Consistent moisture and temperature control also supports the wet granulation process, because a stable feed condition helps a pelletizer produce uniform particles with fewer fines and less rework, which directly reduces energy and material waste across the manufacturing system.

Conclusion

Sustainable practices in the pomace drying stage rely on three linked priorities: suitable high moisture organic waste selection, a staged moisture reduction process from dewatering to composting to rotary drum drying, and disciplined emission and wastewater controls that protect product quality and regulatory performance. A rotary drum dryer-centered production line can convert fruit pomace and other wet residues into consistent organic fertilizer granules, because stable dehydration supports predictable granulation, stronger pellets, and efficient packaging and transport. A professional drying equipment manufacturer- Yushunxin can provide rotary drum dryer solutions designed for modern pomace fertilizer production and moisture control requirements. You can visit: https://www.fertilizerdryer.com/pomace-drying-machine/